One-Stop Custom Printing Packaging Manufacturer

Since 2008, we have been engaged in the design and production of printing and packaging.

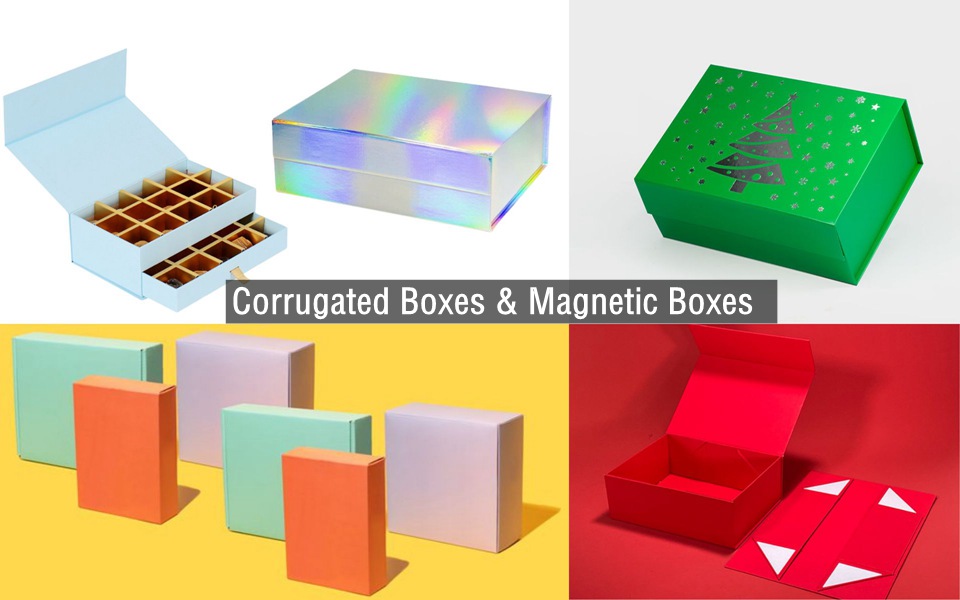

The product line includes stickers, labels, paper boxes, plastic boxes, paper tubes, plastic tubes, magnet gift boxes and cushioning products.

Centralized procurement and manufacturing to reduce costs and increase efficiency

agreen packaging More than a decade of multi-sectoral joint manufacturing production and centralized transportation. This allows the same brand design to be printed in any way, on any medium and maintains the uniformity of the brand.

EPR Production Linkage

Customized EPR customer management and production systems are used uniformly among the company's sub-divisions. This ensures that instructions are communicated consistently.

Advanced equipment and team

We have a number of plastic and paper printing machines as well as HP labeling digital printers. Equipped with experienced production team.

Global shipping experience

Our more than 10 years of experience in global shipping allows us to always match you with the right mode of transportation efficiently and cost-effectively.