Custom Plastic Clamshell Packaging Clamshells Containers

- 3D & 2D software assisted 3-5 days to complete samples

- Custom structure shape and size,Daily capacity 200K

- ISO 9001:2015 & GRS Certified Manufacturer

- Biodegradable & Recyclable Material Options

- Delivery experience in more than 80 countries

- Support Printing and Design of Color Paper Card

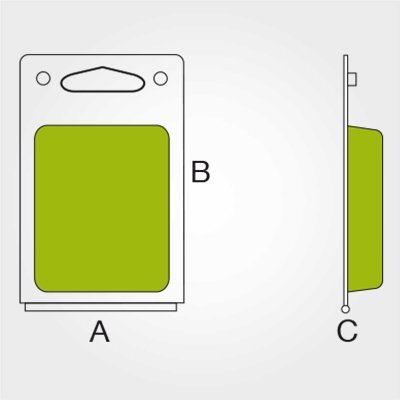

Single side storage clamshell packaging

The Single-Sided cavity is that the cavity (used to place the product) is convex on only one side of the clamshell packaging, its other side is flat, easy to hang on the shelf, save goods space. It is generally used for packing products with small thickness.

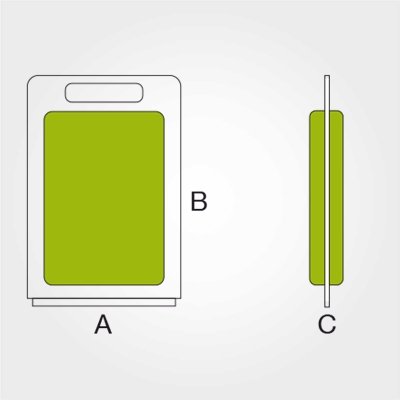

Double side storage clam shell packaging

The Double-Sided cavity is that the cavities on two sides of the clamshell are convex, so it is generally used to packaging the products with relatively thick thickness

About hinge design

Tri-fold Plastic clamshell packaging

Tri-Fold clamshell is quite special and used for packing products that are heavy or need to stand firm. Tri-fold clamshell has a convex cavity on three sides and two living hinges

agreen® packaging was founded in 2008 and located in Shenzhen, China. Our factory has passed ISO9001:2015 and gained praise from Chinese customers in China and Europe. And we have obtained many blister packaging inspection reports and inspection certificates. The thermoforming department has more than 30 employees, 3 QC, 2 QA, and 53 production technology and management personnel. There are 6 automatic production lines

F.A.Q.

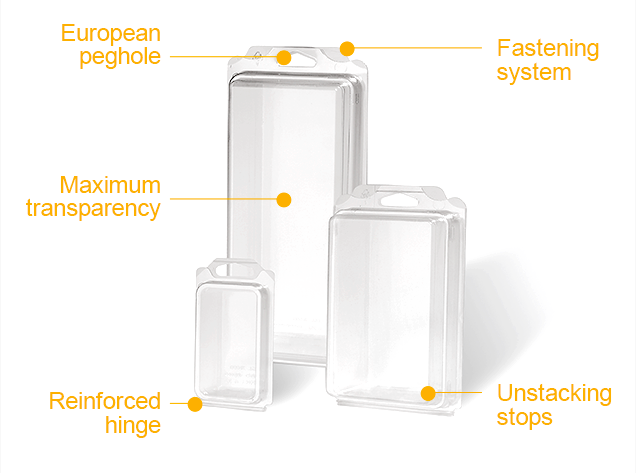

Plastic Blister Packaging is a universal terminology used to describe thermoforming blister packaging. At present, the thermoforming blister package has been widely applied for different products. Clamshell packaging belongs to a kind of blister packaging, it has a container with two halves, the two halves can fully pack and protect the inside products, then joined together by a hinge to control the opening and closing of a blister, just like the shell. Due to the shape and function of this blister packaging are very similar to the shell, so it is called a clamshell box.

The main difference between the plastic clamshells and other blister packages is that other packaging doesn’t have a hinge, and the clamshell pack has a hinge, you can distinguish the clamshell and other blisters by this point. Custom your packaging

1.Single Side Storage Clamshell Packaging

2.Single Side Storage Clamshell Packaging

3.Tri-Fold Clamshell Packaging

The first advantage of clamshell blister is save the labor time to assemble the inside products. The workers just need to put the products into the cavity, then close the clamshell blister packaging. That’s all.

The second advantage of clamshell packaging is the clear material shows the inside products well and protect the inside products from moving. The clients who pay more attention to protect the inside products during transportation would choose the clamshell blister packaging to pack their products.

The last advantage of a clamshell blister pack is the cost. If you want to control the cost of packaging, a clamshell blister would be a good idea. It would be cheaper than box packaging.

In order to fix each item in clamshell packaging safely, we need to customize the clamshell packaging mold for you separately, which will produce a certain mold cost. However, we have a professional clamshell packaging mold department to customize various types of molds for you