What is the clamshell packaging?

Blister packaging is a universal terminology used to describe thermoforming blister packaging. At present, the thermoforming blister package has been widely applied for different products. Clamshell packaging belongs to a kind of blister packaging, it has a container with two halves, the two halves can fully pack and protect the inside products, then joined together by a hinge to control the opening and closing of a blister, just like the shell. Due to the shape and function of this blister packaging are very similar to the shell, so it is called a clamshell box.

The main difference between the plastic clamshells and other blister packages is that other packaging doesn’t have a hinge, and the clamshell pack has a hinge, you can distinguish the clamshell and other blisters by this point.

Application of hinge in clamshell packaging

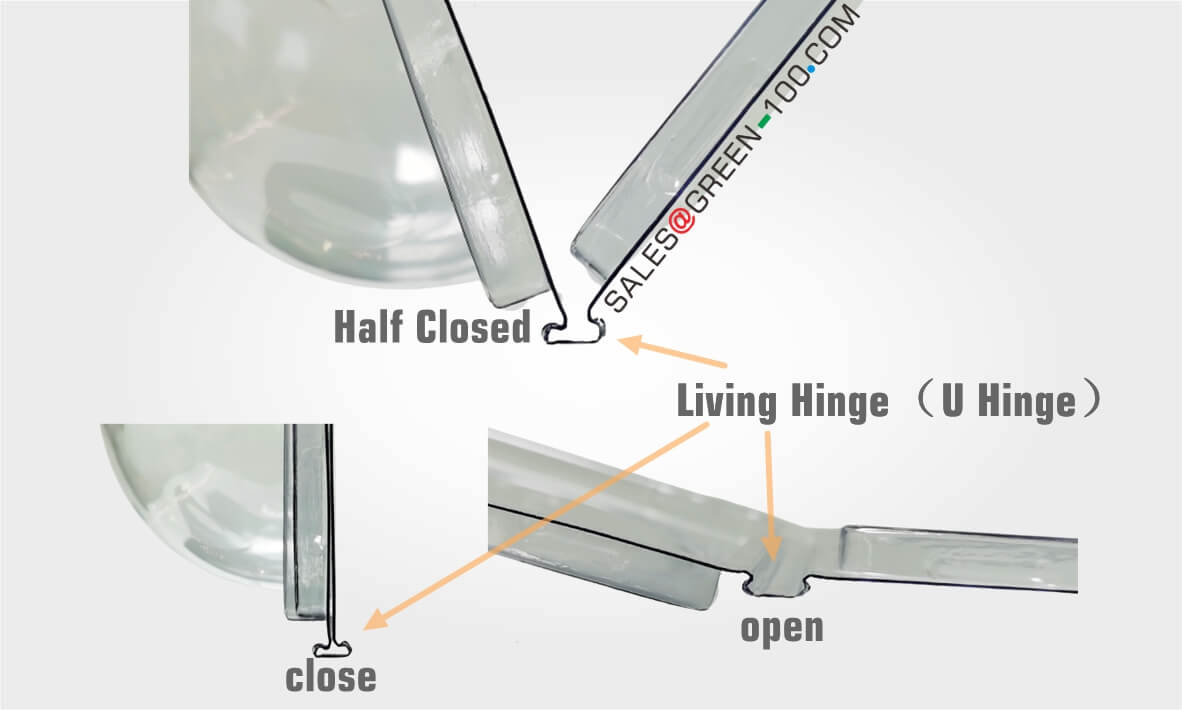

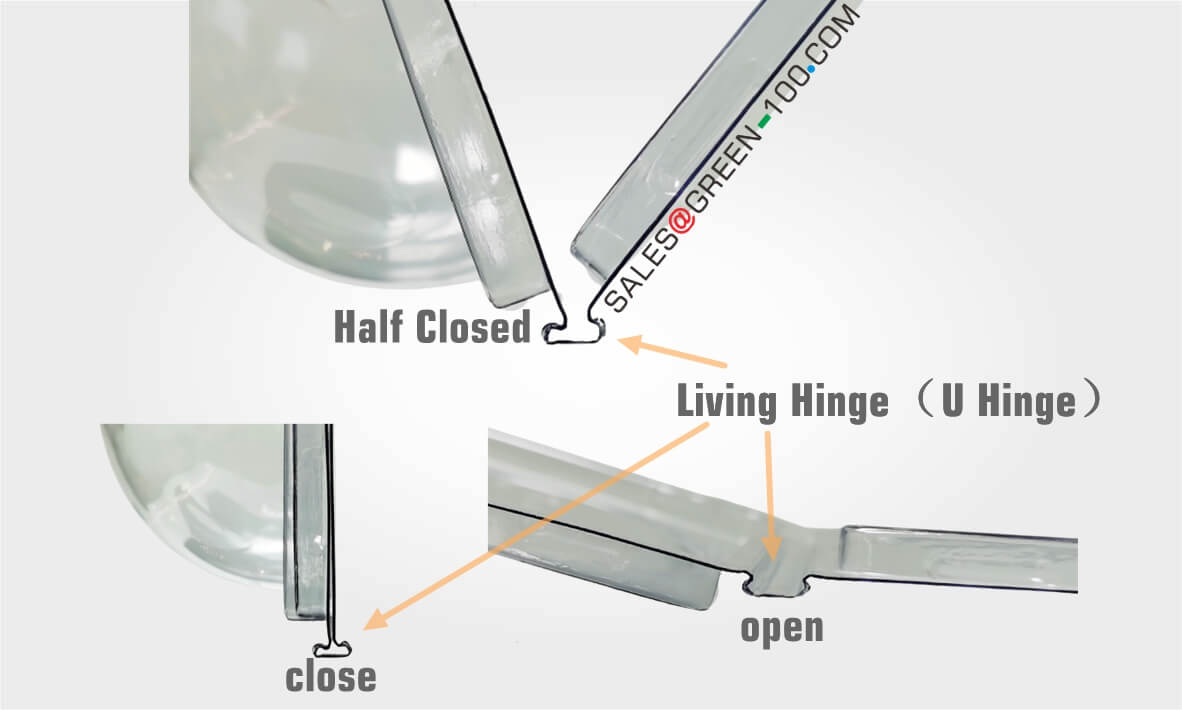

As mentioned above, clamshell boxes are joined the two halves together by a hinge. There are two types of hinge structure, let’s see what’s the difference between them:

Dashed hinge clamshell packaging

The first type is a dashed hinge. The dashed hinge is more beautiful when clamshell sealing, and it is easy to fold. If you want your products in a clamshell package, not only it can be hung on the shelf, but also can stand on a flat surface to display the products, the clamshell with a dashed hinge would be a good choice. The dashed hinge and the cavity on the backside of the plastic clam shells form a relatively small inclination angle, not easy to fall. But the hinge is a dashed line, so only a part of the hinge is joined together, easy to disconnect, the fold time is more, the hinge is more likely to disconnect. At the same time, the material used to make the clamshell is the thicker, the greater the tension between the two halves when the clamshell closes, and the more likely the hinge is to disconnect. Therefore, this type of dashed hinge structure is more suitable for the inside lighter products and the clear clamshell packaging requiring a standing display of products.

living hinge Clamshell Packaging(U Hinge)

The second type is the living hinge, relative to the dashed hinge, with the living hinge in clamshell that will not be a disconnect, high reusable utilization rate.

But the dashed hinge and the cavity on the backside of the clamshell form a relatively big inclination angle when clamshell standing, easy to fall, so the clamshell with living hinge is basically hung on the shelf.

Of course, no matter which one type of hinge you choose, it will not affect the price of eco-friendly clamshells when producing bulk.

Tri-Fold clamshell is quite special and used for packing products that are heavy or need to stand firm. Tri-fold clamshell has a convex cavity on three sides and two living hinges, after clamshell closing, the bottom of the blister package will form a rectangular plane, and the side elevation of the whole packaging shows up a regular triangle. As we all know, triangles have the characteristics of stability, firmness, and pressure resistance, so this triangle bottom can provide the stable platform for the products of the center of gravity imbalance. Of course, it is the most difficult for producing. From plastic clamshell packaging‘s structure design and the original sample mold production, must choose experienced clamshell packaging manufactures, slight size difference and clam shell mold irregularities will lead to the final assembly of the mismatch, resulting in standing instability or tilt.

While we strive to offer our customers very competitive pricing, we don’t sacrifice quality for it. We will use different equipment and production lines to manufacture according to the actual application of your products for the most cost advantage. All products are tested for transparency, wall thickness, hinge strength and “openness”.

The 3 Main Advantages Of Clamshell Blister Packaging

The first advantage of clamshell blister is save the labor time to assemble the inside products. The workers just need to put the products into the cavity, then close the clamshell blister packaging. That’s all.

The second advantage of clamshell packaging is the clear material shows the inside products well and protect the inside products from moving. The clients who pay more attention to protect the inside products during transportation would choose the clamshell blister packaging to pack their products.

The last advantage of clamshell blister pack is the cost. If you want to control the cost of packaging, clamshell blister would be a good idea. It would be cheaper than box packaging.

Practical Application

Clamshell cupcake containers

Macaron clamshell packaging

Clamshell plant packaging

Hardware Tools

Wax Melts

Vape Cartridge

About Clamshell Packaging Advertising Printed Paper Card Applications!